This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3651283 Water Transfer Tube is a critical component designed for use in commercial trucks. It plays a role in the vehicle’s cooling system by facilitating the movement of coolant between various components, contributing to the overall efficiency and reliability of the engine. Understanding its purpose and operation is key to maintaining the truck’s performance and longevity.

Basic Concepts of Water Transfer Tubes

A water transfer tube is a conduit within a truck’s cooling system that ensures a consistent flow of coolant, which is vital for regulating engine temperature. By maintaining optimal engine temperature, this part helps prevent overheating and potential engine damage 1.

Purpose of the Cummins 3651283 Water Transfer Tube

The Cummins 3651283 Water Transfer Tube is engineered to direct coolant flow within the truck’s cooling system. It connects different parts of the system, allowing coolant to circulate effectively. This circulation is important for dissipating heat generated by the engine, thereby supporting stable engine operation under various conditions 2.

Key Features

The Cummins 3651283 Water Transfer Tube is characterized by its robust design and the materials used in its construction. It is made from durable materials that resist corrosion and wear, ensuring longevity and reliable performance. The tube’s design includes precise fittings and connections that facilitate secure attachment within the cooling system, contributing to its overall effectiveness 3.

Benefits

The use of the Cummins 3651283 Water Transfer Tube offers several advantages. It enhances coolant flow within the system, which can lead to more efficient heat dissipation. This improved flow contributes to better engine protection against overheating. Additionally, the tube’s durable construction increases the reliability of the cooling system, especially in demanding operating environments 4.

Installation Considerations

Proper installation of the Cummins 3651283 Water Transfer Tube is important for ensuring its effectiveness. Installation should follow manufacturer guidelines, which may include specific prerequisites and the use of appropriate tools. Careful attention to fitting and securing the tube within the cooling system is necessary to prevent leaks and ensure optimal performance.

Troubleshooting Common Issues

Common issues with water transfer tubes may include leaks or blockages. These problems can often be identified through visual inspection or by monitoring the cooling system’s performance. Troubleshooting steps may involve checking connections for tightness, inspecting for signs of wear or damage, and cleaning or replacing the tube if necessary to restore proper function.

Maintenance Tips

To ensure the Cummins 3651283 Water Transfer Tube continues to perform effectively, regular maintenance is recommended. This includes periodic inspection for signs of wear, corrosion, or damage. Cleaning the tube and its connections can help prevent blockages. Following manufacturer guidelines for replacement intervals can also contribute to the longevity and reliability of the cooling system.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a reputation for producing high-quality components for commercial vehicles. The company’s commitment to innovation and excellence is reflected in its wide range of products, including the Cummins 3651283 Water Transfer Tube. Cummins’ focus on quality and performance makes its components a popular choice among fleet operators and maintenance professionals.

Role of Part 3651283 Water Transfer Tube in Engine Systems

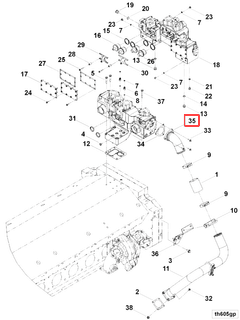

The Part 3651283 Water Transfer Tube is integral to the efficient operation of several key components within engine systems.

Interaction with the Housing

The Water Transfer Tube interfaces directly with the engine housing, facilitating the smooth and consistent flow of coolant. This interaction ensures that the housing maintains an optimal temperature, which is essential for the longevity and performance of the engine. The tube’s precise fit within the housing allows for minimal coolant leakage, thereby enhancing the overall cooling efficiency of the system.

Coordination with the Thermostat

In conjunction with the thermostat, the Water Transfer Tube plays a significant role in regulating engine temperature. The thermostat controls the flow of coolant based on the engine’s temperature, and the Water Transfer Tube ensures that this coolant reaches the necessary areas promptly. This coordinated effort helps in maintaining the engine within its ideal operating temperature range, preventing overheating and ensuring consistent performance.

Integration with the Thermostat Housing

The Water Transfer Tube is also designed to work seamlessly with the thermostat housing. This integration is vital for the proper circulation of coolant throughout the engine system. The tube’s connection to the thermostat housing allows for efficient heat exchange, which is crucial for the thermostat to function correctly. This, in turn, helps in stabilizing the engine temperature and protecting the engine from potential damage due to overheating.

Conclusion

The Cummins 3651283 Water Transfer Tube is a vital component in the cooling systems of commercial trucks, ensuring efficient coolant flow and optimal engine temperature regulation. Its robust design, durable materials, and precise engineering contribute to the reliability and performance of the engine. Regular maintenance and proper installation are essential for maximizing the benefits of this Cummins part.

-

Brach, R. Matthew. SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International, 2023.

↩ -

ElSayed, Mohamed PE. Fundamentals of Integrated Vehicle Realization. SAE International, 2017.

↩ -

Lakshminarayanan, P. A., and Nayak, Nagaraj S. Critical Component Wear in Heavy Duty Engines. John Wiley & Sons, 2011.

↩ -

Norman, Andrew. Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc, 2016.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.