More than 10 are currently available

Ships within 1 business day

Minimum Quantity 4

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3678786 O Ring Seal is a vital component for commercial trucks, manufactured by Cummins, a reputable name in the automotive industry. This O Ring Seal is designed to ensure the efficient operation of truck systems, with a material composition tailored to meet the demanding requirements of commercial vehicle applications.

Basic Concepts of O Ring Seals

An O Ring Seal is a type of gasket with a circular cross-section, used to create a seal between two or more parts, preventing fluid or gas leakage. When compressed between flanges or in a groove, it deforms slightly to create a tight seal. O Ring Seals are widely used in mechanical systems for their simplicity, effectiveness, and versatility in sealing applications 1.

Role of the 3678786 O Ring Seal in Truck Operation

This Cummins part ensures the integrity of seals within the truck’s systems, typically placed in areas requiring fluid or gas containment, such as the engine, transmission, or hydraulic systems. By providing a reliable seal, it helps maintain system efficiency and prevent leaks that could lead to performance issues or damage 2.

Key Features

The Cummins 3678786 O Ring Seal is characterized by its material composition, designed to withstand harsh conditions encountered in commercial truck applications, and its durability, ensuring long-term reliability. Its design specifications are optimized for its intended use, providing a secure and effective seal in demanding environments 3.

Benefits

The use of this Cummins part offers several benefits, including improved sealing efficiency within the truck’s systems, reducing the risk of leaks and maintaining system performance. Its resistance to wear and tear ensures it can withstand the rigors of commercial truck operation, contributing to the overall reliability of the truck’s systems. Additionally, its design and material properties help extend the service life of the seal, offering value to fleet operators.

Troubleshooting and Maintenance

Common issues associated with O Ring Seals include wear, deformation, and failure due to exposure to extreme temperatures or incompatible fluids. Troubleshooting these problems involves inspecting the seal for signs of damage or degradation and replacing it if necessary. Regular maintenance practices, such as checking for proper installation and ensuring compatibility with system fluids, can help ensure the longevity and effectiveness of the Cummins 3678786 O Ring Seal.

About Cummins

Cummins is a renowned manufacturer in the automotive industry, known for its innovation and commitment to quality. The company has established a reputation for producing reliable and high-performance components for commercial vehicles. Cummins’ dedication to advancing technology and meeting the needs of its customers underscores its position as a leader in the industry.

Cummins O Ring Seal 3678786 Compatibility

The Cummins O Ring Seal part number 3678786 is a critical component designed to ensure a tight seal in various engine applications. This part is engineered to fit seamlessly with a range of Cummins engines, providing essential sealing properties that help maintain engine performance and efficiency.

Compatible Engines

- 15N CM2380 M104B

- 6B5.9

- 6C8.3

- B3.3

- B4.5 CM2350 B129B

- B4.5 RGT

- B5.6 CM2670 B152B

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7 G CMOH6.0 B125

- B6.7S

- D4.0 CM2620 D103B

- F2.8 CM2620 F135B

- F3.8 CM2350 F120B

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

- G855

- G855 CM558

- GTA38 G CMEICS G116C

- GTA855 CM558 (CM2358) G101

- ISB (Chrysler)

- ISB CM2150

- ISB CM850

- ISB/ISD4.5 CM2150 B119

Grouping of Compatible Engines

The Cummins O Ring Seal 3678786 is designed to fit a diverse array of engines, including both older and newer models. Here is a breakdown of the engines grouped by their series or common characteristics:

B Series Engines

- B3.3

- B4.5 CM2350 B129B

- B4.5 RGT

- B5.6 CM2670 B152B

- B6.7 CM2350 B135B

- B6.7 CM2670 B153B

- B6.7 CM2670 B164C

- B6.7 G CMOH6.0 B125

- B6.7S

F Series Engines

- F2.8 CM2620 F135B

- F3.8 CM2350 F120B

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

G Series Engines

- G855

- G855 CM558

- GTA38 G CMEICS G116C

- GTA855 CM558 (CM2358) G101

ISB Series Engines

- ISB (Chrysler)

- ISB CM2150

- ISB CM850

- ISB/ISD4.5 CM2150 B119

Other Engines

- 15N CM2380 M104B

- 6B5.9

- 6C8.3

- D4.0 CM2620 D103B

This O Ring Seal is a versatile part that ensures a reliable seal in various engine configurations, contributing to the overall efficiency and longevity of the engine.

Role of Part 3678786 O Ring Seal in Engine Systems

The Part 3678786 O Ring Seal is integral to the functionality and efficiency of various engine systems. Its application spans across multiple components, ensuring optimal performance and reliability.

Air Compressor Upfit Kit

In the air compressor upfit kit, the O ring seal is utilized to create a tight seal between the compressor and its mounting surface. This prevents air leaks, ensuring the compressor operates at peak efficiency.

Camshaft Gear

For the camshaft gear, the O ring seal is employed to seal the gear to the camshaft, preventing oil leakage. This maintains proper lubrication and reduces wear on the camshaft and gear.

Cooling System Gasket Set

Within the cooling system gasket set, the O ring seal is crucial for sealing connections between various components, such as the water pump and cylinder block. This ensures coolant flows efficiently without leaks, maintaining engine temperature.

Crankcase Breather Plumbing

In the crankcase breather plumbing, the O ring seal is used to seal connections, allowing crankcase gases to escape while preventing external contaminants from entering the crankcase.

Crankshaft and Bearings

For the crankshaft and bearings, the O ring seal is applied to seal oil passages, ensuring consistent lubrication and protecting the crankshaft and bearings from contaminants.

Cylinder Block Hardware Kit

In the cylinder block hardware kit, the O ring seal is used to seal various ports and passages, maintaining the integrity of the cylinder block and ensuring proper fluid flow.

Exhaust Recirculation Cooler Kit

The exhaust recirculation cooler kit utilizes the O ring seal to create a secure seal between the cooler and its connections, ensuring efficient recirculation of exhaust gases and reducing emissions.

Flywheel Housing Plumbing

For the flywheel housing plumbing, the O ring seal is essential for sealing oil passages, ensuring proper lubrication of the flywheel and related components.

Fuel Filter Plumbing

In the fuel filter plumbing, the O ring seal is used to seal connections, ensuring a leak-free fuel supply to the engine and maintaining fuel system integrity.

Fuel Module Coolant Plumbing

The fuel module coolant plumbing relies on the O ring seal to create secure connections, ensuring efficient cooling of the fuel module and preventing leaks.

Fuel Plumbing Kit

For the fuel plumbing kit, the O ring seal is crucial for sealing fuel lines and connections, ensuring a consistent and leak-free fuel supply to the engine.

Clocked Plumbing

In clocked plumbing, the O ring seal is used to seal connections at specific angles, ensuring proper alignment and sealing of fluid passages.

Male Union Elbow

The male union elbow utilizes the O ring seal to create a secure and leak-free connection between pipes, ensuring efficient fluid flow.

Oil Bypass Filter

For the oil bypass filter, the O ring seal is essential for sealing the filter to its housing, ensuring proper filtration and maintaining oil quality.

Oil Cooler Kit

In the oil cooler kit, the O ring seal is used to seal connections between the cooler and oil lines, ensuring efficient cooling of the engine oil.

Oil Cooler Water Plumbing

The oil cooler water plumbing relies on the O ring seal to create secure connections, ensuring efficient heat exchange between the oil and coolant.

Oil Drain Connection

For the oil drain connection, the O ring seal is crucial for sealing the drain plug, preventing oil leaks during oil changes.

Oil Filter Cooler Head

In the oil filter cooler head, the O ring seal is used to seal the cooler to the oil filter, ensuring efficient cooling and filtration of the engine oil.

Oil Level Sensor

The oil level sensor utilizes the O ring seal to create a secure connection to the oil pan, ensuring accurate oil level readings and preventing leaks.

Priming Pump Kit

For the priming pump kit, the O ring seal is essential for sealing the pump to its housing, ensuring efficient priming of the fuel system.

Torque Converter Oil Cooler

In the torque converter oil cooler, the O ring seal is used to seal connections, ensuring efficient cooling of the torque converter fluid.

Vent Engine Coolant Assembly

The vent engine coolant assembly relies on the O ring seal to create secure connections, ensuring proper venting of the coolant system and preventing leaks.

Water Pump

For the water pump, the O ring seal is crucial for sealing the pump to the engine block, ensuring efficient circulation of coolant and maintaining engine temperature.

Wiring Retainer Bracket

In the wiring retainer bracket, the O ring seal is used to seal connections, ensuring secure and organized wiring within the engine compartment.

XPI JV System Cummins HD

Finally, the XPI JV System Cummins HD utilizes the O ring seal to seal various connections within the fuel system, ensuring efficient and reliable fuel delivery to the engine.

Conclusion

The Cummins 3678786 O Ring Seal is a critical component for ensuring the efficient operation of commercial truck systems. Its design, material composition, and compatibility with a wide range of Cummins engines make it an essential part for maintaining system integrity and performance. Regular maintenance and proper installation are key to ensuring the longevity and effectiveness of this O Ring Seal.

SPECIFICATIONS

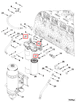

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Retaining Ring | 4 | 3519641 |

| Lockplate | 4 | 3522904 |

| Shaft Wheel Rotor | 1 | 3521033 |

| Hexagon Head Set Screw | 8 | 3521225 |

| Split Ring Seal | 1 | 3523412 |

| Split Ring Seal | 1 | 3521442 |

| Shim | 1 | 3524418 |

| Oil Baffle | 1 | 3524419 |

| Hexagon Head Set Screw | 4 | 3525073 |

| Turbocharger Heat Shield | 1 | 3536588 |

| Regular Hexagon Nut | 1 | 3529372 |

| v Band Clamp | 1 | 3532617 |

| Turbocharger Thrust Bearing | 1 | 3536914 |

| Rectangular Ring Seal | 1 | 3534405 |

| Thrust Collar | 1 | 3591522 |

| Turbocharger Bearing Housing | 1 | 3536591 |

| Lock Nut | 1 | 3771005 |

| Retaining Ring | 1 | 3537301 |

| Turbocharger Noise Baffle | 1 | 3539137 |

| O-Ring Seal | 1 | 3591282 |

| Turbocharger Bearing | 2 | 3598528 |

| Oil Slinger | 1 | 4036307 |

| Turbocharger Diffuser | 1 | 4036445 |

| Turbocharger Compressor Impeller | 1 | 5323938 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.