This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3539209 Hexagon Head Set Screw is a specialized fastener designed for use in commercial trucks. Its primary purpose is to secure components within the truck’s mechanical assemblies, ensuring stability and reliability under demanding conditions. This screw is integral to maintaining the structural integrity and operational efficiency of various truck systems.

Basic Concepts of Hexagon Head Set Screws

A Hexagon Head Set Screw is a type of fastener characterized by its hexagonal head, which allows for secure and precise tightening using a hex key or socket wrench 1. The design of the screw enables it to be driven into a pre-tapped hole, where it exerts pressure against the mating surface to create a tight fit. This mechanism is essential in applications where vibration resistance and secure fastening are required.

Purpose and Role in Truck Operation

The Cummins 3539209 Hexagon Head Set Screw plays a significant role in the operation and maintenance of commercial trucks. It is used in various components such as engine mounts, transmission housings, and chassis assemblies. By providing a secure and vibration-resistant connection, this screw helps maintain the alignment and integrity of critical truck parts, contributing to overall vehicle performance and safety 2.

Key Features

The Cummins 3539209 Hexagon Head Set Screw is crafted from high-quality materials, typically alloy steel, to ensure durability and resistance to wear. It features a fine thread pitch, which allows for precise adjustments and secure fastening. The hexagonal head design facilitates easy installation and removal using standard tools, enhancing efficiency in maintenance procedures 3.

Benefits

Using the Cummins 3539209 Hexagon Head Set Screw offers several advantages. Its robust material composition and precise threading contribute to improved security and reliability in fastening applications. The ease of installation with common tools reduces maintenance time, while its durability ensures long-term performance in heavy-duty environments 4.

Installation and Usage

Proper installation of the Cummins 3539209 Hexagon Head Set Screw involves using the appropriate hex key or socket wrench to drive it into a pre-tapped hole. It is important to ensure that the screw is tightened to the manufacturer’s specified torque settings to achieve optimal performance and avoid over-tightening, which could damage the screw or the mating surface.

Troubleshooting and Maintenance

Common issues with Hexagon Head Set Screws include loosening due to vibration or corrosion. Regular inspection and tightening can help address these problems. In cases where corrosion is present, it may be necessary to replace the screw to maintain secure fastening. Proper lubrication during installation can also help prevent seizing and extend the lifespan of the screw.

Safety Considerations

When working with Hexagon Head Set Screws, it is important to follow safety practices to prevent accidents. This includes using the correct tools for installation and removal, wearing appropriate personal protective equipment, and ensuring that all fasteners are properly torqued to avoid overloading or failure. Adherence to these practices helps maintain a safe working environment and ensures compliance with industry standards.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel engines and related components. With a history of innovation and quality, Cummins is recognized for producing reliable and high-performance parts, such as the 3539209 Hexagon Head Set Screw, which are designed to meet the rigorous demands of commercial truck applications.

Compatibility with Cummins Engines

The Cummins Hexagon Head Set Screw part number 3539209 is a versatile component that is compatible with a range of Cummins engines. This screw is designed to provide a secure fastening solution in various engine applications, ensuring reliability and durability.

Compatible Engines

6B5.9, 6C8.3, B4.5, B5.9 G, B5.9 GAS PLUS CM556, B6.7S, C GAS PLUS CM556, C8.3 G, G8.3, ISB CM550, ISB/ISD6.7 CM2150 SN, ISB5.9 CM2880 B110, ISB5.9 CM2880 B127, ISB5.9G CM2180, ISBE CM2150, ISBE CM800, ISBE4 CM850, ISC CM554, ISC CM850, ISL CM554, ISL9 CM2150 SN, ISL9.5 CM2880 L138, L8.9, L8.9 CM2670 L134C, L8.9 L121

The 3539209 Hexagon Head Set Screw is engineered to fit seamlessly within the specified engine models. This compatibility ensures that the screw can be used across different engine types, providing a standardized solution for securing various engine components.

Engine Grouping

Group 1: 6B5.9, 6C8.3, B4.5, B5.9 G, B5.9 GAS PLUS CM556, B6.7S, C GAS PLUS CM556, C8.3 G, G8.3

These engines are typically mid-range and smaller in size, often used in applications requiring moderate power output. The 3539209 screw is suitable for securing smaller components and ensuring precise assembly.

Group 2: ISB CM550, ISB/ISD6.7 CM2150 SN, ISB5.9 CM2880 B110, ISB5.9 CM2880 B127, ISB5.9G CM2180

These engines are part of the ISB series, known for their robust performance and reliability. The 3539209 screw is ideal for securing larger and more critical components within these engines.

Group 3: ISBE CM2150, ISBE CM800, ISBE4 CM850, ISC CM554, ISC CM850, ISL CM554, ISL9 CM2150 SN, ISL9.5 CM2880 L138

These engines are part of the ISBE, ISC, and ISL series, offering a range of power outputs and applications. The 3539209 screw is designed to fit within these engines, providing a reliable fastening solution for various components.

Group 4: L8.9, L8.9 CM2670 L134C, L8.9 L121

These engines are part of the L series, known for their high power output and durability. The 3539209 screw is compatible with these engines, ensuring secure fastening of critical components.

The 3539209 Hexagon Head Set Screw is a crucial component in maintaining the integrity and performance of Cummins engines. Its compatibility across various engine models ensures that it can be used in a wide range of applications, providing a reliable fastening solution for engine components.

Role in Various Engine Components

The 3539209 Hexagon Head Set Screw is instrumental in securing and maintaining the integrity of various components within engine systems. Its application spans across multiple assemblies and kits, ensuring that parts remain firmly in place under operational stress.

Actuator Bracket Kit

In the actuator bracket kit, the Hexagon Head Set Screw is used to fasten the bracket to the engine block or turbocharger housing. This secure attachment is essential for the proper functioning of the actuator, which controls the position of the wastegate or variable geometry vanes.

Aftermarket Turbocharger

When installing an aftermarket turbocharger, the Hexagon Head Set Screw plays a key role in mounting the turbocharger to the engine. It ensures that the turbocharger is held securely in place, preventing any movement that could lead to leaks or failure.

Assembly Kit

Within an assembly kit, this set screw is often used to secure smaller components such as sensors or additional brackets. Its hexagonal head allows for easy tightening and loosening, making it ideal for assembly line use.

Bracket Kit

The bracket kit utilizes the Hexagon Head Set Screw to attach brackets to various engine components. These brackets may support turbochargers, intercoolers, or other performance parts, ensuring they remain stable during engine operation.

Core Assembly

In the core assembly of a turbocharger, the set screw is used to secure critical components such as the compressor wheel or turbine housing. This ensures that all parts within the core assembly remain aligned and function correctly.

Turbocharger Actuator Kit

The turbocharger actuator kit relies on the Hexagon Head Set Screw to mount the actuator to the turbocharger housing. This secure attachment is vital for the actuator to effectively control the wastegate or variable geometry vanes.

Turbocharger Arrangement

In a turbocharger arrangement, which may include multiple turbochargers in a twin-turbo or sequential turbo setup, the set screw is used to ensure that all components are tightly secured. This is important for maintaining the efficiency and reliability of the turbocharger system.

Turbocharger Bracket Kit

The turbocharger bracket kit uses the Hexagon Head Set Screw to attach the turbocharger to the engine block or manifold. This secure mounting is essential for withstanding the high temperatures and pressures generated by the turbocharger.

Turbocharger Campaign Kit

In a turbocharger campaign kit, which may include various replacement parts and upgrades, the set screw is used to ensure that all new components are properly installed and secured. This helps in maintaining the performance and longevity of the turbocharger system.

Turbocharger Gasket Kit

While the primary role of a gasket kit is to provide sealing between components, the Hexagon Head Set Screw is often used to secure the gasket in place, ensuring a tight and leak-free seal.

Turbocharger Housing Repair Kit

In a housing repair kit, the set screw is used to reassemble and secure the turbocharger housing after repairs. This ensures that the housing remains intact and functions correctly.

Turbocharger Kit

A comprehensive turbocharger kit will include the Hexagon Head Set Screw for various applications, from mounting the turbocharger to securing smaller components within the kit. This versatility makes it a fundamental part in the installation and maintenance of turbocharger systems.

Wastegate Turbine Housing Kit

In a wastegate turbine housing kit, the set screw is used to attach the wastegate to the turbine housing. This secure attachment is crucial for the wastegate to effectively control the turbocharger’s boost pressure.

Conclusion

The Cummins 3539209 Hexagon Head Set Screw is a vital component in the maintenance and operation of commercial trucks and Cummins engines. Its robust design, compatibility with various engine models, and versatile applications make it an essential part for securing critical components within engine systems. Proper installation, regular maintenance, and adherence to safety practices ensure the longevity and reliability of this Cummins part.

-

Kershaw, John F. SAE International’s Dictionary for Automotive Engineers. SAE International, 2023.

↩ -

Majewski, Addy, and Hannu Jaskelainen. Diesel Emissions and Their Control: Second Edition. SAE International, 2023.

↩ -

Reif, Konrad, ed. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩

SPECIFICATIONS

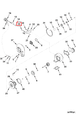

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| Turbocharger Bearing | 2 | 3503100 |

| Split Ring Seal | 1 | 3758848 |

| Split Ring Seal | 1 | 3756754 |

| Retaining Ring | 4 | 3762259 |

| Retaining Ring | 1 | 3527566 |

| Oil Baffle | 1 | 3528104 |

| O Ring Seal | 1 | 3528933 |

| Oil Seal Plate | 1 | 3530923 |

| Oil Slinger | 1 | 3530924 |

| Turbocharger Thrust Bearing | 1 | 3531419 |

| Thrust Collar | 1 | 3534451 |

| Shaft Wheel Rotor | 1 | 3539805 |

| Lock Nut | 1 | 3596402 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.